360 YIELD RESULTS

360 Y-DROP

360 Y-DROP VS. COULTER

360 Y-DROP on a self-propelled sprayer allows the grower to extend their window of application to the time when a corn plant is taking up the majority of N (V8-V12), while most coulter systems run in the V2-V6 growth stages.

The other key difference is placement. A traditional coulter places N in the middle of the row. The disadvantage is it may take the plant time

to take-up N via the roots and potentially have more exposure to leaching before reaching the roots.

In comparison, 360 Y-DROP places N right next to the base of the plant where it moves down into the soil and the roots.

360 Y-DROP

NITROGEN PLACEMENT AND TIMING

Growers who sidedress commonly use a sidedress tool bar with a coulter and place UAN in the center of the row.

We tested coulter practice vs. 360 Y-DROP. The differences between these two systems is mainly placement and timing.

360 CHAINROLL

Three weeks after we harvested our stalk roll test plot we could already see the microbial activity on the stalks cut with 360 CHAINROLL.

See the difference between 360 CHAINROLL residue breakdown and OEM stalk rolls.

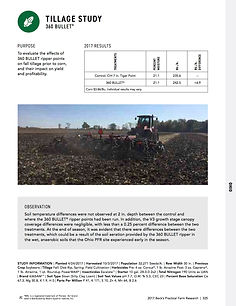

360 BULLET

DEEP TILLAGE TRIAL

In this trial we evaluated the subsurface soil profile to compare OEM 7" ripper points to 360 BULLET points.

The test compared the amount of undisturbed subsoil, soil density over compacted soil and yield.

CROP ROTATION AND

POPULATION STUDY

In this trial, we evaluated 26 hybrids and their performance to help us make our decision for next year's crop plan. Each hybrid is planted at two populations and over two different crop rotation conditions - corn after corn and corn after soybeans.

The information is used to identify new hybrids that will be added to the commercial corn rotation and to improve rate and placement on all commercial corn hybrids. It summarizes the average performance of the different populations and rotations.

INDUSTRY DATA